Fasteners and Machining: Necessary Elements for Accuracy Manufacturing

Fasteners and Machining: Necessary Elements for Accuracy Manufacturing

Blog Article

Navigating the Globe of Fasteners and Machining: Approaches for Precision and Speed

In the complex world of fasteners and machining, the quest for accuracy and rate is a perpetual obstacle that demands thorough interest to detail and calculated preparation. From understanding the diverse array of fastener types to picking optimum products that can hold up against strenuous demands, each action in the procedure plays a critical role in attaining the wanted result. Accuracy machining methods further raise the complexity of this craft, calling for a delicate equilibrium between technical experience and ingenious strategies. As we explore the techniques that can improve both rate and efficiency in this domain name, the interaction between high quality control measures and operational excellence becomes a crucial focal point.

Understanding Fastener Types

When selecting fasteners for a job, recognizing the numerous kinds offered is essential for making certain optimal efficiency and reliability. Fasteners come in a wide variety of kinds, each developed for details applications and demands. Screws are utilized with nuts to hold materials together, while screws are flexible fasteners that can be used with or without a nut, depending on the application. Nuts, on the other hand, are inside threaded bolts that companion with screws or bolts, providing a protected hold. Washing machines are crucial for distributing the load of the fastener and avoiding damages to the product being secured. Furthermore, rivets are irreversible bolts that are perfect for applications where disassembly is not needed. Comprehending the differences between these bolt types is essential for selecting the right one for the task, guaranteeing that the connection is strong, resilient, and dependable. By selecting the proper bolt kind, you can enhance the performance and longevity of your task - Fasteners and Machining.

Selecting the Right Products

Understanding the significance of choosing the appropriate products is critical in making sure the optimum efficiency and reliability of the chosen bolt types reviewed previously. When it concerns fasteners and machining applications, the material option plays a crucial duty in figuring out the general stamina, longevity, corrosion resistance, and compatibility with the intended atmosphere. Various products use differing properties that can dramatically impact the efficiency of the fasteners.

Common products utilized for fasteners include steel, stainless steel, aluminum, brass, and titanium, each having its one-of-a-kind staminas and weak points. Steel is renowned for its high toughness and resilience, making it appropriate for a vast array of applications. Picking the ideal product involves taking into consideration variables such as stamina demands, ecological conditions, and spending plan restraints to make sure the wanted efficiency and durability of the bolts.

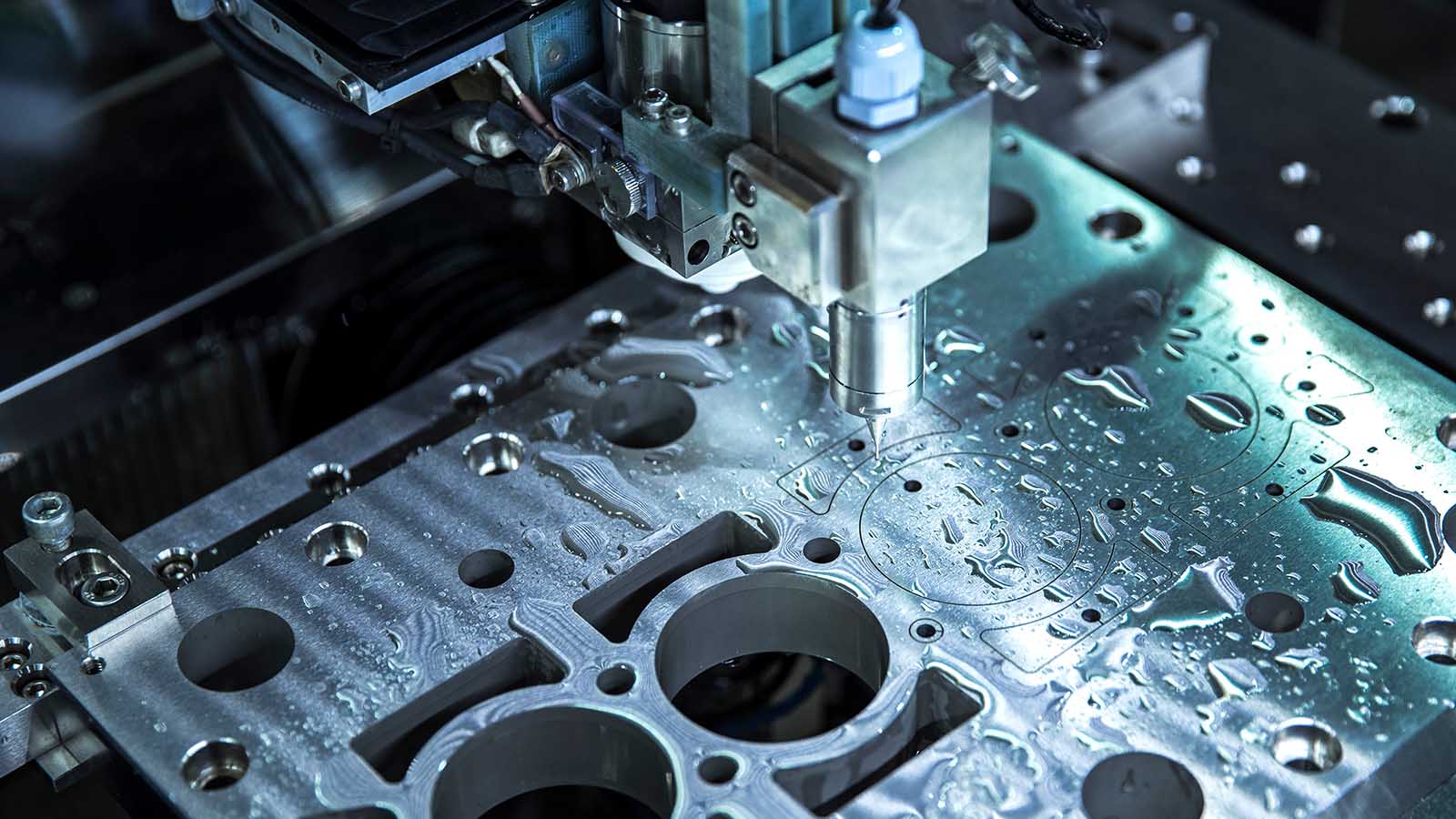

Accuracy Machining Techniques

In enhancement to CNC machining, other accuracy methods like grinding, turning, milling, and boring play vital duties in fastener production. Grinding aids accomplish great surface area finishes and tight dimensional tolerances, while transforming is frequently made use of to create cylindrical parts with specific diameters. Milling and drilling procedures are essential for shaping and producing openings in bolts, ensuring they fulfill precise requirements and feature correctly.

Enhancing Rate and Performance

To enhance bolt manufacturing procedures, it is important to simplify operations and apply efficient strategies that enhance accuracy machining methods. One vital method for improving speed and effectiveness is the application of lean manufacturing principles. By reducing waste hop over to these guys and focusing on continual enhancement, lean practices aid optimize and get rid of bottlenecks workflow. Furthermore, purchasing automation modern technologies can dramatically enhance manufacturing speed. Automated systems can handle recurring jobs with accuracy and rate, enabling workers to concentrate on more complex and value-added tasks. Taking On Just-In-Time (JIT) stock administration can likewise improve performance by making sure that the right materials are available at the appropriate time, lessening excess stock and lowering preparations. Fostering a culture of cooperation and communication among group members can improve total efficiency by promoting openness, analytical, and innovation. By combining these techniques, suppliers can achieve a balance in between rate and accuracy, inevitably improving their one-upmanship in the bolt market.

Top Quality Control Measures

Implementing rigorous high quality control actions is crucial in making certain the reliability and uniformity of fastener products in check over here the manufacturing procedure. Quality assurance steps include various phases, beginning with the selection of resources to the last assessment of the completed bolts. One fundamental element of quality control is carrying out complete product inspections to verify conformity with requirements. This involves examining elements such as material toughness, resilience, and structure to ensure that the fasteners fulfill sector standards. Additionally, checking the machining refines is vital to copyright dimensional precision and surface coating quality. Making use of advanced modern technology, such as computerized examination systems and precision measuring devices, can boost the precision and performance of high quality control treatments.

Regular calibration of equipment and machinery is imperative to preserve consistency in production and guarantee that bolts fulfill the required tolerances. Applying strict procedures for identifying and dealing with non-conformities or flaws is important in protecting against substandard products from going into the market. By establishing a informative post thorough top quality control structure, manufacturers can maintain the track record of their brand name and deliver bolts that meet the highest possible requirements of performance and toughness.

Verdict

In the complex world of bolts and machining, the mission for accuracy and speed is a perpetual obstacle that requires careful focus to information and critical preparation. When it comes to bolts and machining applications, the product choice plays a crucial role in establishing the total toughness, resilience, deterioration resistance, and compatibility with the intended atmosphere. Precision machining includes different sophisticated methods that guarantee the tight resistances and requirements needed for bolts.In enhancement to CNC machining, other precision methods like grinding, turning, milling, and boring play vital functions in bolt manufacturing.To maximize bolt production procedures, it is essential to streamline procedures and implement effective approaches that complement accuracy machining techniques.

Report this page